Abstract

Treatment of Molasses-Based Distillery Wastewater in a Pilot- Scale Anaerobic Sequencing Batch Reactor (ASBR)

High-strength distillery wastewater, also called stillage or spent wash, contains high concentrations of organic and inorganic pollutants. Considering the standard allowable limit for effluent discharge, pollutants must be reduced from distillery wastewater before being released into the watercourse. This study examined the use of anaerobic sequencing batch reactor (ASBR) in a pilot-scale treatment of molasses-based distillery wastewater. ASBR was designed and fabricated using a 1,000 L capacity plastic container. The mixture consisted of 65% inoculum and 35% diluted wastewater. Influent was diluted at a proportion of 1 part wastewater and 2 parts water due to the high COD concentration of raw distillery wastewater. The inoculum was anaerobically-treated sludge obtained from an existing wastewater treatment facility. ASBR trials were done with varying reaction (stirring) durations, i.e., 8, 24 and 48 h operated for 24, 40 and 64 h cycle, respectively. Two trials were done per operating conditions. Highest COD (60%) and BOD (86%) reductions were observed in ASBR operation with 8 h react time. Biogas production in ASBR with 8 h react time also had the highest methane content (72%) compared to those with 24 h and 48 h reaction periods having 66% and 50% methane, respectively. Sludge by-product after ASBR operations had 0.91 to 1.02% total NPK (nitrogen, phosphorus, potassium), which can be utilized as soil ameliorant. Posttreatment of ASBR-treated effluent is necessary to attain the allowable discharge limit.

Author(s):

Myra L Tansengco, David L Herrera, Judith C Tejano

Abstract | Full-Text | PDF

Share this

Google scholar citation report

Citations : 5001

Electronic Journal of Biology received 5001 citations as per google scholar report

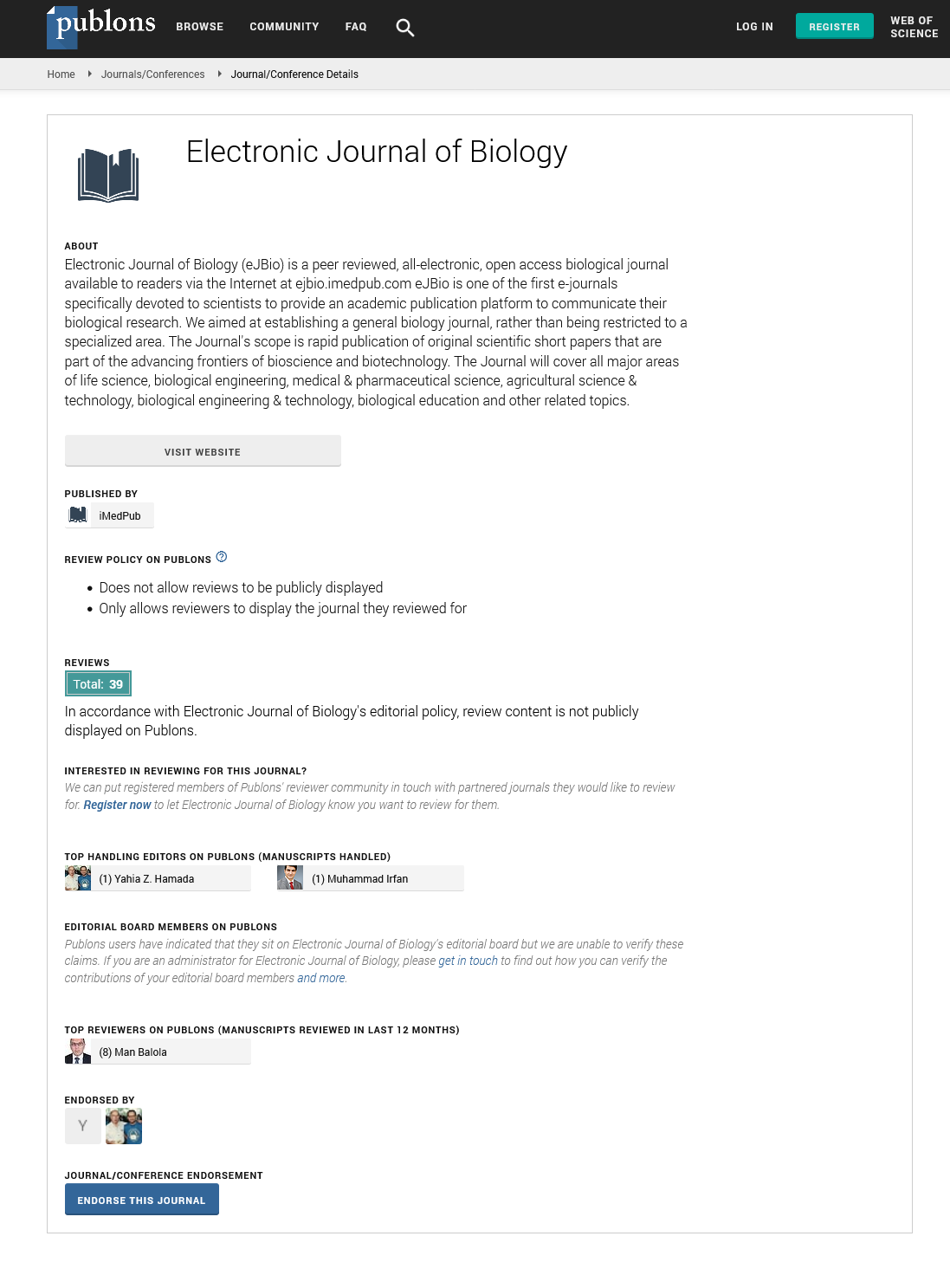

Electronic Journal of Biology peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Electronic Journals Library

- Zoological Records

- WorldCat

- Proquest Summons

- Publons

- MIAR

- Openaccessarticles.com

- Secret Search Engine Labs

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences